CRAFTSMANSHIP

THE WATCH CASE OF TIMETHIS

TIMETHIS choose 316L for its watch case. TIMETHIS has abandoned the production line work, but employed die forging technology in making sturdy watch case. And each case looks bright and clean as silk through independent grinding and polishing in high-tech processing center.

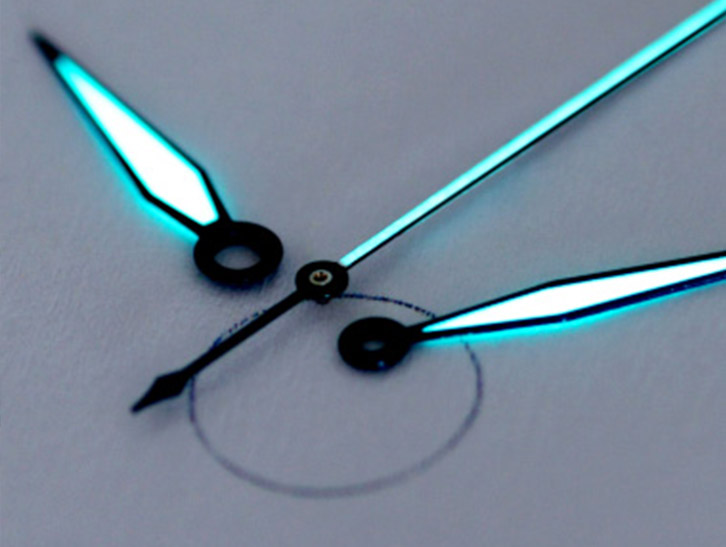

THE WATCH HANDS OF TIMETHIS

For the heated blue watch hands of TIMETHIS, the hand base is made by accurate rounding and then fired through the traditional hot bluing technology. All steel parts are heated to 300 ℃(540 F), making the hand appearance oxidized and becoming azure blue and then turning to deep blue. The temperature of flame must be accurately controlled so as to ensure the consistent color and luster, and the rate of finished products cannot be higher than 60%. And for the firing process, the technique of craftsman is tested, and furthermore embodying the best ingenuity of craftsmanship.

The Crystal of TIMETHIS Watch

The sapphire lens is employed extensively for TIMETHIS watch. The sapphire bar, produced originally from Europe, is made into sapphire crystal surface through fine abrasive machining. In order to ensure the best readability in different brightness and from different angles, the sapphire crystal has conducted anti-dazzle treatment. And the coating firm is conducted in vacuum oven at the temperature of 280℃ (536 F). In this way, the visible ray refraction can be removed effectively. The dome shape is also known as sapphire crystal with big hook face. Because of grinding and polishing being very complicated, the rate of finished products, even we have well-developed manufacture technology today, is rather low. The more is an attitude that TIMETHIS makes the sapphire lens by means of this technology.

THE LUMINENT OF TIMETHIS WATCH

The TIMETHIS watch coated with noctilucine material can ensure that the luminous material use by TIMETHIS watch has none radioactivity. Super-Lumi Nova use cold-light chemical combined coating material can emit more lasting and more bright light than the traditional luminescent coating after illumination, and the noctilucent brightness can reach one hundred times of the tritium luminous intensity.